Learning Activities 2.1 – 2.4: Marshmallow Measurements, Pressure Calculation, Components of the Rough Vacuum Trainer System, and Gas Flow Paths

Summary of Learning Activities

Learning Activity 2.1: Pressure Exerted by the Marshmallow on a Table Top

Learning Activity 2.2: Components of the Rough Vacuum Equipment Trainer System

- Measuring the dimensions of a cylindrically-shaped object (marshmallow) to calculate force and pressure of the object when it comes in contact with a flat surface.

- Calculating pressures exerted by the marshmallow on the table top before expanding the marshmallow under vacuum and after compressing it when the system is vented.

- Identifying system components of the rough vacuum equipment trainer system and gas flow paths.

- Practice measuring linear dimensions of the cylindrical object.

- Calculate the surface area of the object in contact with the table top.

- Calculate the force and pressure the object exerts on the table top.

- Present the final calculated pressure value in correct units of Pascal with the proper number of significant digits.

- Demonstrate how pressure exerted by an object on a tabletop changes when the object expands or contracts.

- Identify the components of a rough vacuum equipment training system.

- Identify gas flow paths and states of valves for each flow path.

Suggested Pre-lab Assignment

-

Read Section 3.4 of the E-book and list 5 components of the rough vacuum system with short description of their functionality.

-

Read Section 3.5 of the E-book and draw a symbol for each vacuum system component from Question 1.

Theoretical Background

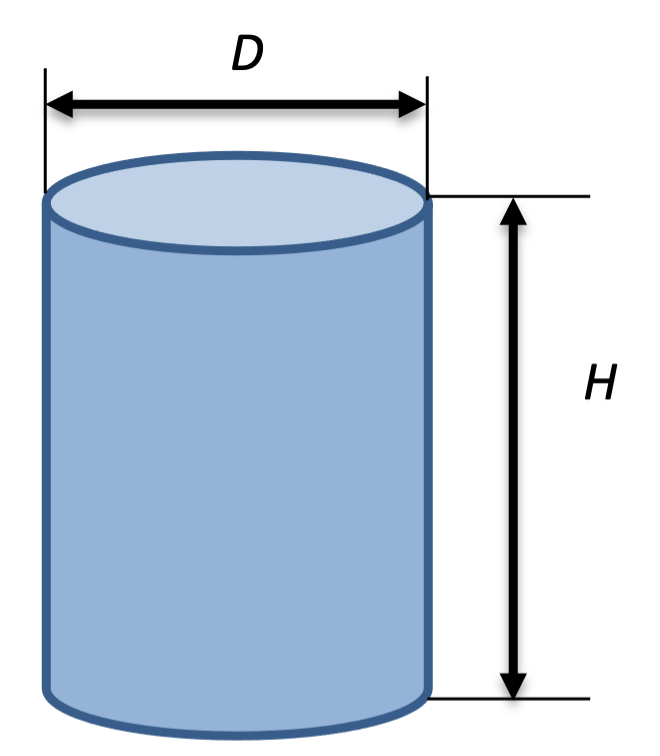

Figure 2.2 shows cylindrically-shaped object with diameter D and height H.

Surface area of the flat bottom part of the cylinder is calculated using Equation 2.1:

[latex]\begin{equation} A_{bottom} = \frac {\pi D^2}{4} \qquad \qquad \qquad \qquad (Eq. \thinspace 2.1) \end{equation}[/latex]

Then, force exerted by this object on the flat surface is calculated as shown in Equation 2.2:

[latex]\begin{equation} F_{g} \thinspace = mg \qquad \qquad \qquad \qquad \left( Eq.2.2 \right) \end{equation}[/latex]

where Fg is the force of gravity or weight of the object in units of Newton (N), m is the mass in units of kilograms (kg), and g = 9.81 m/s2 is the acceleration due to gravity.

Finally, pressure is calculated using Equation 2.3:

[latex]\begin{equation} P = \frac {F_g}{A_{bottom}} = \frac {F_g}{\pi D^2 / 4} = \frac {4F_g}{\pi D^2} \qquad \qquad \qquad (Eq. \thinspace 2.3) \end{equation}[/latex]

where P is the pressure in units of Pascal, Fg is the weight of the object in Newtons, and D is the diameter of the cylindrical object in meters.

For example, let’s calculate the pressure exerted by the cylindrical object with a diameter of 4.5 cm and mass of 54.0 g on a flat surface.

First, convert a measurement in units of grams (g) to kilograms (kg) as follows:

[latex]\begin{equation} 1 = \frac {0.001 kg}{1g} = \frac {1 kg}{1,000g} \end{equation}[/latex]

or, simply divide the mass in grams by 1,000 g/kg as indicated below:

[latex]\begin{equation} m = 54.0g = \frac {54.0g}{1,000g/kg} = 0.0540 kg = 5.40 \times 10^{-2} kg \end{equation}[/latex]

Note that the answer above is given in scientific notation with three significant digits.

Next, calculate the weight of the object as:

[latex]\begin{equation} F_{g} = (0.0540 kg) \times (9.81 m/s^2) = 0.529 N \end{equation}[/latex]

Before calculating the pressure, we need to convert diameter from centimeters to meters using the conversion factor 1 m = 100 cm or, simply, dividing the measurement in units of centimeters by 100 cm/m to obtain meters:

[latex]\begin{equation} D = 4.5 cm = \frac {4.5 \cancel{cm}}{100 \cancel{cm}/m} = 0.045 m = 4.5 \times 10^{-2} m \end{equation}[/latex]

Then calculate the area of the bottom part of the object that comes in contact with the flat surface using Equation 2.1:

[latex]\begin{equation} A_{bottom} = \frac {\pi \left( 0.045m \right)^2}{4} = 0.00159 m^2 = 1.59 \times 10^{-3} m^2 \end{equation}[/latex]

And, finally, the pressure exerted by the cylindrical object in contact with the flat surface is calculated using Equation 2.3 to two significant digits:

[latex]\begin{equation} P = \frac {0.529 N}{0.00159 m^2} = 330 Pascal = 3.30 \times 10^2 Pa \end{equation}[/latex]

When the object expands as the pressure surrounding it decreases under vacuum conditions, its weight does not change, but Abottom will get larger which will result in less pressure on the flat surface.

Equipment and Materials

- 1 Ruler

- 1 Mass Scale or Mass Balance

- 1 Marshmallow

- RVET (rough vacuum equipment trainer)

Procedure

Learning Activity 2.1: Pressure Exerted by the Marshmallow on a Table Top

You may use data obtained for the marshmallow measured during Learning Activity 1.1 or measure the mass and diameter of a new marshmallow using a mass scale/balance and ruler.

- Calculate the pressure exerted by the face of the marshmallow in contact with a table top before expanding the marshmallow under vacuum.

a. Mass of the marshmallow in grams (g) and kilograms (kg):

b. Diameter of the marshmallow in centimeters (cm) and meters (m):

c. Force exerted by the bottom of the marshmallow on a flat surface in Newtons (N) (remember, 1 N = 1 kg•m/s2 (kilogram-meter/second2)):

d. Pressure exerted by the bottom of the marshmallow on a flat surface in Pascals (Pa) (remember, 1 Pa = 1 N/m2 (Newton/meter2)):

Learning Activity 2.2: Components of the Rough Vacuum Equipment Trainer System

- What are the components of the Rough Vacuum Equipment Trainer (RVET) system? You may watch Video 2.1 to answer this question.

a.

b.

c.

d.

e.

Video 2.1. Typical rough vacuum system components. Video produced by Elena Brewer and Richard Hill, SUNY Erie Community College.

Learning Activity 2.3: Gas Flow Paths

- What states do the following components need to be in for the system to be pumping down? You may watch Video 2.2 to help answer this question.

a. Vacuum chamber: open closed doesn't matter b. Roughing valve: open closed doesn't matter c. Venting valve: open closed doesn't matter d. Roughing pump: open closed doesn't matter Video 2.2. Rough vacuum system pump-down procedure. Video produced by Elena Brewer and Richard Hill, SUNY Erie Community College.

What states do the following components need to be in for the system to be venting? You may watch Video 2.3 to help answer this question.

| a. Vacuum chamber: | open | closed | doesn't matter |

| b. Roughing valve: | open | closed | doesn't matter |

| c. Venting valve: | open | closed | doesn't matter |

| d. Roughing pump: | open | closed | doesn't matter |

Video 2.3. Rough vacuum system venting procedure. Video produced by Elena Brewer and Richard Hill, SUNY Erie Community College.

Learning Activity 2.4: Expanding a Marshmallow under Vacuum

-

What happened to the marshmallow in vacuum at pressures close to atmospheric pressure (just after pump-down process started)?

-

What happened to the marshmallow after the roughing valve was closed at lower pressures (higher vacuum)?

-

What happened to the marshmallow when the air was allowed to vent back into the system?

After-class Assignment

Write down which marshmallow your group used in Learning Activity 2.1 and use that same one for calculations below.

-

Calculate the pressure the face of the marshmallow will exert when it comes in contact with a table top after the marshmallow has shrunk.

a. Mass of the marshmallow in grams (g) and kilograms (kg):

b. Diameter of the marshmallow in centimeters (cm) and meters (m):

c. Force exerted by the bottom of the marshmallow on a flat surface in Newtons (N) (remember, 1 N = 1 kg•m/s2 (kilogram-meter/second2)):

d. Pressure exerted by the bottom of the marshmallow on a flat surface in Pascals (Pa) (remember, 1 Pa = 1 N/m2 (Newton/meter2)):

-

Draw a simple schematic for the RVET system using the symbols shown in class. Label the different gauges and valves. Draw arrows to show the gas flow in the RVET system when it is being (a) pumped down and (b) vented.

This work is supported by the National Science Foundation under grant number ATE DUE 2000454. Any opinions, findings, and conclusions or recommendations expressed in this e-book are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Media Attributions

- Figure 2.2. is licensed under a CC BY-NC-SA (Attribution NonCommercial ShareAlike) license