Rough Vacuum Equipment Training (RVET) System

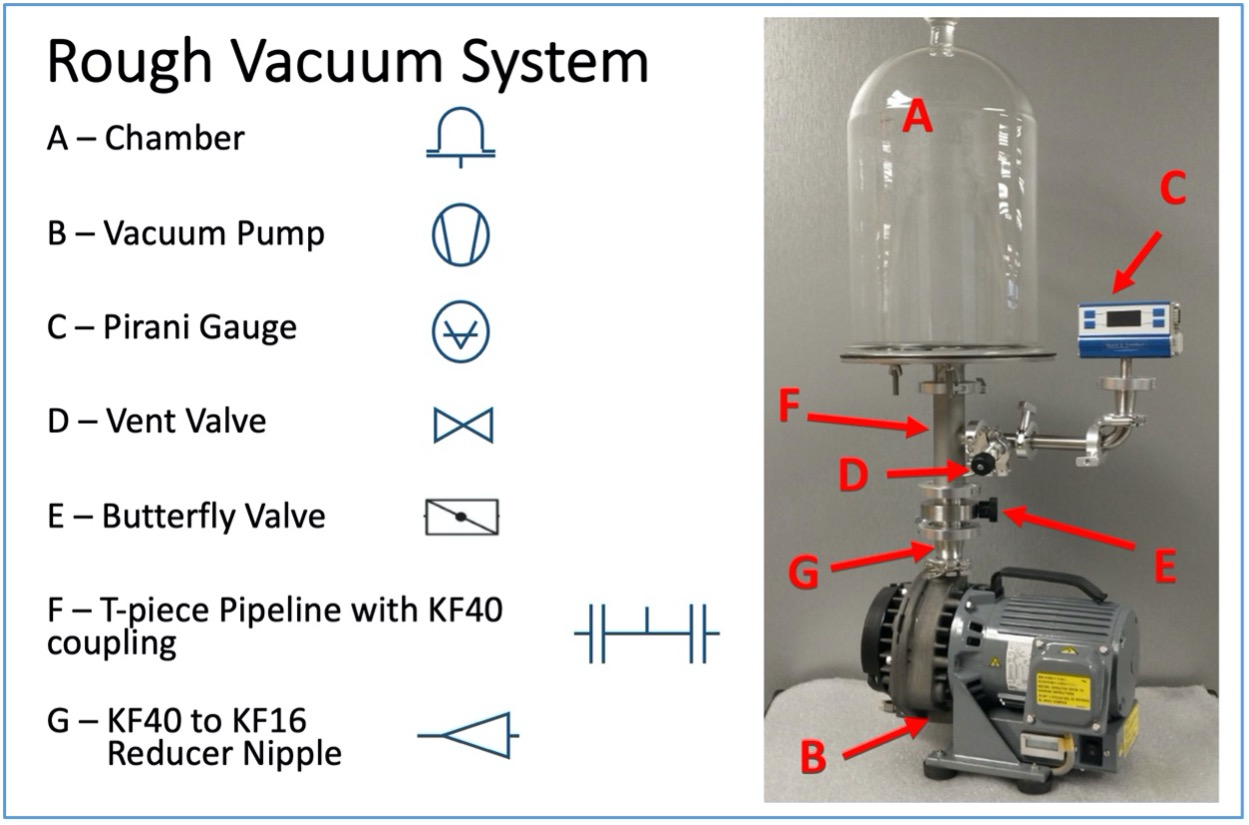

A simple Rough Vacuum Equipment Training (RVET) system, at a minimum, consists of an interconnection of a rough vacuum pump, chamber, vacuum gauge for measuring pressure, two valves, and piping to interconnect the main components. These system components can be arranged in different geometries. One version of a RVET system, used at SUNY Erie Community College, is shown in Figure 1.

Using the RVET shown in Figure 1, most of the learning activities in this lab manual can be performed.

Instructor’s Corner

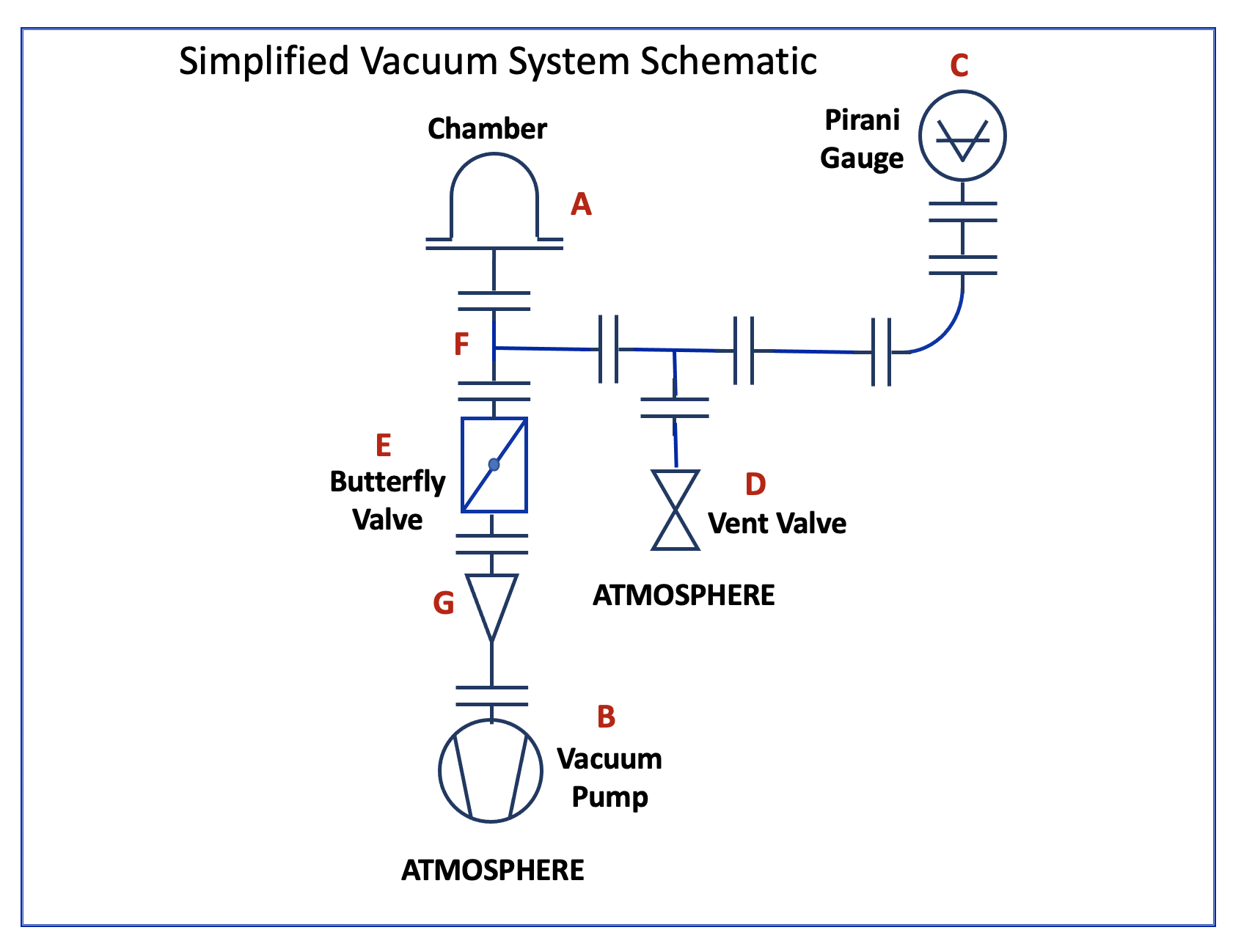

Figure 2 shows schematic for a sample RVET system. This RVET system is sufficient to conducts Learning Activities 1 – 9.

Bill of Materials:

- Vacuum chamber – base plate, https://andersondahlen.com, part number AVT-04012015-15, quantity – 1

- Vacuum chamber – glass bell jar, https://www.fishersci.com, part number S30955 or similar (this item might already be owned by physics or chemistry department), quantity – 1

- Vacuum chamber – rubber gasket, https://www.grainger.com, part number 1MYB6 (requires cutting to fit the base plate and (optional) feed through openings), quantity – 1

- Vacuum chamber – base plate plug, https://www.lesker.com, part number FBH-1005, quantity – 2

- Rough vacuum pump, https://www.lesker.com, Edwards RV3 part number A65201906 or similar, quantity – 1

- KF40 Butterfly valve, https://www.lesker.com, part number KBV015MSQF40, quantity – 1

- Vent valve, https://www.lesker.com, part number C35103000, quantity – 1

- KF40 full nipple, https://www.tedpella.com, part number 92324-40, quantity – 2 (4, if additional vacuum gauge needs to be connected)

- KF40 to 25 compact conical reducer, https://www.tedpella.com, part number 92450-4025, quantity – 1

- KF40 90° elbow, https://www.tedpella.com, part number 92300-40, quantity – 1 (2, if additional vacuum gauge needs to be connected)

- KF40 equal tee, https://www.tedpella.com, part number 92320-40, quantity – 1 (Note: need to be replaced by KF40 equal cross, part number 92334-40, if second vacuum gauge needs to be connected)

- KF40 tee with KF16 for vent valve, https://www.tedpella.com, part number 02322-4016, quantity – 1

- KF40 wing nut clamp, machined aluminum, https://www.tedpella.com, part number 92211-40, quantity – 8 (13, if additional vacuum gauge needs to be connected)

- KF40 centering O-ring, https://www.tedpella.com, part number 92211-40, quantity – 8 (13, if additional vacuum gauge needs to be connected)

- KF25 wing nut clamp, machined aluminum, https://www.tedpella.com, part number 92211-25, quantity – 1

- KF25 centering O-ring, https://www.tedpella.com, part number 92211-25, quantity – 1

- KF16 wing nut clamp, machined aluminum, https://www.tedpella.com, part number 92211-16, quantity – 1 (2, if additional vacuum gauge needs to be connected)

- KF16 centering O-ring, https://www.tedpella.com, part number 92211-16, quantity – 1 (2, if additional vacuum gauge needs to be connected)

- KF40 quick vacuum test gauge (Bourdon Gauge), https://www.tedpella.com, part number 92489-40, quantity – 1

- KF40 adaptor to 1/8″ female NPT for quick vacuum test gauge, https://www.tedpella.com, part number 92464-40, quantity – 1

-

Convection-enhanced Pirani vacuum gauge, https://www.lesker.com, part number KJL300808, quantity – 1

OR

Busy Bee combination (capacitance diaphragm and Pirani) gauge, https://www.instrutechinc.com, part number PCM301, quantity – 1.

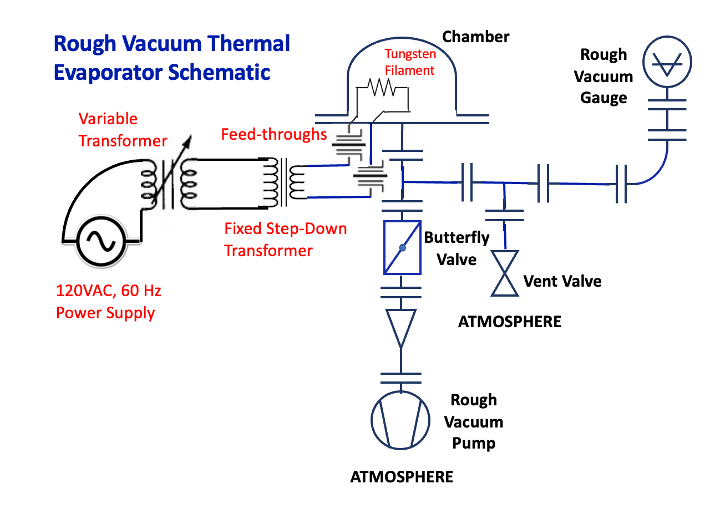

Learning Activity 10 is an example of application of a rough vacuum system to deposit thin film material on a substrate. It requires additional modifications to convert it to a thermal evaporator as shown in Figure 3.

Bill of Materials for Additional Equipment:

- Power feed through, 50V/400A, https://www.lesker.com, part number EFT-0013754, quantity – 2

- 3-string tungsten filament 4-coils, https://www.tedpella.com, part number 84-12, quantity – 5 (each package contains 5 filaments)

- Fixed step-down transformer (primary – 117V, 126VA, 60Hz; Secondary – 6.3V at 20A or 3.15V at 40A), https://www.mouser.com/, part number E207860, quantity – 1

- Variable transformer, Superior, 3PN116C (Ratings: 1.4 KVA, 60 Hz, Input: 120V, Output: 0-140V), various suppliers, quantity – 1

- Wires: 8 AWG for wires connecting fixed transformer secondary to the feedthroughs, 18 AWG for the rest of the wires.

This work is supported by the National Science Foundation under grant number 2000454. Any opinions, findings, and conclusions or recommendations expressed in this e-book are those of the authors and do not necessarily reflect the views of the National Science Foundation.